Adhere to the principle of "quality first, reputation first, customer first"

Service&Case Presentation

FOUR SERVICES

4 one-stop customized services integrating production, research and development, sales, and technical services.

Large self owned factorieswith sufficient inventory

After sales guaranteemanufacturer direct sales

Support customizedfree samples

Modern management division of labor and cooperation, large production capacity

Diverse types

Worry free after-sales service

Engineer one-on-one service

Professional production line

01.Consult customerservice

02. Customers providesamples, sample customization preliminary plan

03. Calculating Prices

04. Confirm the price and signthe contract, with a 30%advance payment

05. Engineer's one-on-one,service confirmationplan drawing

06. Assembly production

07. After debugging,

Confirm again at the factory

Confirm again at the factory

08. Pay 60% ofthe final payment

09. On site installationand debuggingtechnical training

10. Delivery acceptancepassed Pay theremaining 10%

CUSTOMIZED SERVICE PROCESS

If the fault issue is unclear,please consult the onlinecustomer service directly.

Consult

01

Engineers conduct one-on-one,preliminary analysis of problems

Analysis

02

Confirm the repair plan andsend the sample

Prepare a plan

03

Received samplerepair quotation

Quotation

04

Confirm the repair plan as soon as possible and repair it on the same day

Maintenance

05

Returned on the sameday after repair

Send it back

06

DELIVERY AND REPAIR SERVICE PROCESS

Used for quenching, annealing, tempering, quenching and tempering of various metal workpieces.

Heat treatment process

Stainless steel annealing

Steel pipe heating

Surface quenching of large workpieces

Axial segmented quenching

By heating the metal to a certain temperature, the solder is melted, thereby connecting metals of the same or different materials together.

Welding

Welding of milling (hinge) knives

Powder cutting knife welding

Valve welding

High frequency welding

Various metal materials are heated to a certain temperature and then forged into other shapes.

Hot forging

Heating of rod head

Copper hot forging

Round steel heat transfer

Intermediate frequency heating of copper and aluminum

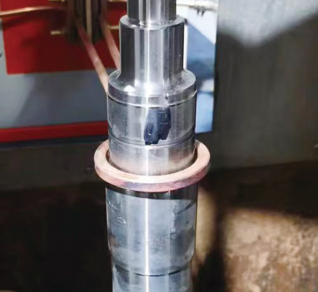

Heat the metal to a certain temperature and use the principle of thermal expansion and contraction for hot fitting.

Hot coordination

Motor rotor heat sleeve

Aluminum shell hot fit

Wind cannon thermal coordination

Aluminum shell heatingof air compressor

By heating the workpiece, the hardness of the metal material changes.

Quench

Wire rod quenching

Flat quenching

Chain quenching

Surface quenching of motor shaft

Heat various metals to a certain temperature until they melt, and cast them into products or melt them into water.