Product Center

▲ (1): Basic principle:

As a closed-loop power control method, it is mainly used for high/medium frequency induction heating equipment (high-frequency machines) to control the output power of the heating equipment,

To keep the workpiece at a constant temperature set point, the principle is to turn on the foot switch (18) of the machine → at this time, the starting port (19) of the controlled equipment is activated

Relay action, activate high/medium frequency equipment → At the same time, the power control terminal (A-B-C) automatically adjusts the power of high/medium frequency equipment to achieve temperature control

Power supply voltage: 220VAC, power consumption less than 10W

Distance coefficient: 75:1

◆ Probe cable length: 2.4M

◆ Repetition accuracy: 1℃

◆ Laser aiming: It can be switched on and off at will. If the laser aiming is enabled for 80 seconds and there is no operation on the laser aiming switch, it will automatically turn off after 80 seconds

◆ Digital emissivity adjustment

◆ Working environment temperature: Host ≤ 50 ℃ Humidity: 10% -80% Non fiber optic probe: Temperature ≤ 50 ℃ Humidity: 10% -80%

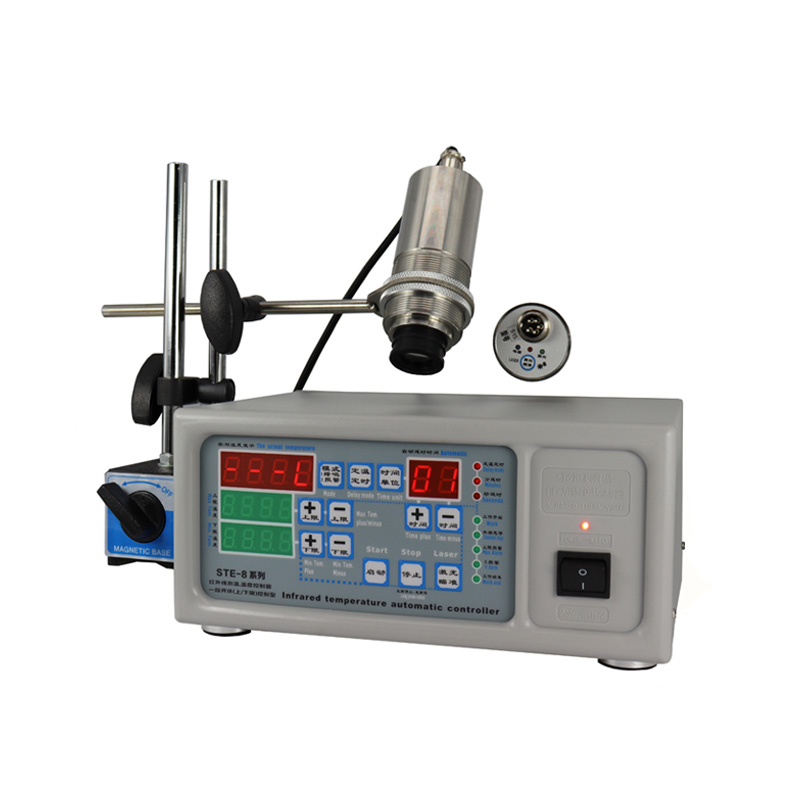

◆ Appearance specifications: Host 175 (front and rear) × 240 (width) × 110mm (height) mm Probe diameter 45 × 120mm

Weight: Host: 3Kg+Probe holder: 1.3Kg+Local foot switch+Interface cable+Power cord=4.7Kg (approximately)