Product Center

800L CNC quenching machine tool

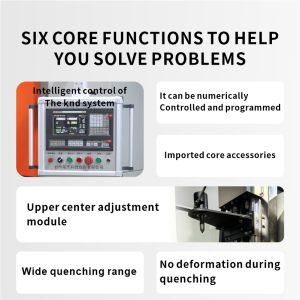

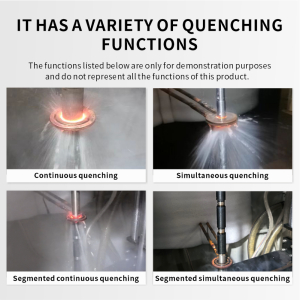

CNC control system: Humanized CNC design with functions such as continuous quenching, simultaneous quenching, segmented continuous quenching, segmented simultaneous quenching, etc. The PLC touch screen is easy to operate, real-time display, and can store more than 100 processes. The quenching hardness is high, the speed is fast, the quenching does not deform, and the top cone can move up and down. It has the characteristics of energy conservation, environmental protection, intelligence, automation, less oxidation, and less deformation, saving time and effort. The quenching process does not require manual adjustment. The program is set up and the equipment automatically completes the quenching process

Main equipment technical parameters and configuration:

project | parameter | project | parameter |

Workstation | 1 | maximum workpiece weight | 300KG |

Maximum clamping part length | 800MM | Quenching feed rate | 6-3000mm/min |

Maximum clamping part diameter | 300MM | Transformer moves quickly | 3000mm/min |

Maximum quenching length | 800MM | Numerical Control System Control Accuracy | 0.001mm |

Numerical Control System | Kane Emperor System | servo motor | MiG with brake motor |

operating mode | Automatic or manual (CNC programming) | ||

Machine tool functions | Automatic lifting, rotation, spraying, scanning, segmented quenching | ||

cover an area | Length 1280MM * Width 680MM * Height 2100mm | ||

Main components and brands of equipment:

Main component names | Brand | Main component names | Brand |

Numerical Control System | KND | Screw rod | (Domestic) |

servo motor | MiG brake belt motor | electrical equipment | chint |

transformer | Dongguan Guangcheng | frequency converter | DELTA |

drive | De Ou | Sheet Metal | Mingtai |